Specifications

Curing Time

This product will normally cure in 2 hours at 15 °C to accept light foot traffic. Full wear resistance is achieved over 7 days (at a minimum constant temp of

15 °C). Water should not be allowed to lie on the surface for at least 7 days.

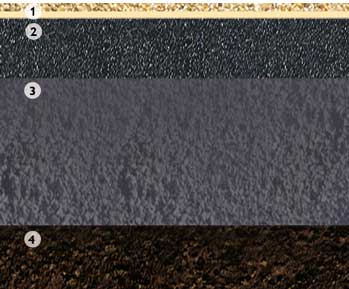

Surface Dressing Make Up

2. Prepared Surface

3. Resin (pigment to suit stone aggregates)

4. Scattered 1-4mm Stone Aggragate

5. Optional Clear Seal Coat

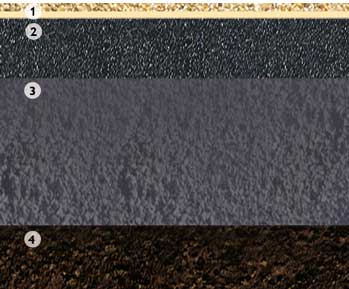

Sub Base Requirements for Tarmac (Depending on usage)

Private Driveways

2. Binder Course - Laid by others in well compacted layers to minimum fall of 1.5%. A 50mm depth of hot rolled asphalt (HRA)

3. Sub Base - Laid by others in well compacted layers to minimum fall of 1.5%. A 150-225mm depth of well-compacted non-frost susceptible Type 1 granular sub base to SHW claue 803 or locally available secondary recycled aggregates which comply with the requirements of the specification for highway works for sub bases

4. Sub Grade

Pathways

2. Binder Course - Laid by others in well compacted layers to minimum fall of 1.5% A 50mm depth of hot rolled asphalt (HRA)

3. Sub Base - Laid by others in well compacted layers to minimum fall of 1.5%. A 100mm depth of well-compacted non-frost susceptible Type 1 granular sub base to SHW claue 803 or locally available secondary recycled aggregates which comply with the requirements of the specification for highway works for sub bases

4. Sub Grade

Access Road

2. Binder Course - Laid by others in well compacted layers to minimum fall of 1.5% A 50mm depth of hot rolled asphalt (HRA)

3. Road Base - Laid by others in well compacted layers to minimum fall of 1.5%. A 70 mm depth of AC 32 dense base asphalt concrete max 100/150 pen to BS EN 13108-1:2006 (bituminous macadam)

4. Sub Base - Laid by others in well compacted layers to minimum fall of 1.5%. A 200-350mm depth of well-compacted non-frost susceptible Type 1 granular sub base to SHW claue 803 or locally available secondary recycled aggregates which comply with the requirements of the SHW works for sub bases

5. Capping Layer (if required)

6. Sub Grade

Sub Base Requirements for Cement (Depending on usage)

2. PAV1/C30 Concrete for pathways and landscaped areas. PAV2/C35 Concrete for access roads and private driveways. Thickness depends on usage

3. Metal Road Matting. Required on Medium - Heavy use areas

4. Damp proof membrane

5. 100-150mm of compacted Type 1 Granular sub-base

6. Sub Grade

Typical construction for fibre-reinforced slab. Maximum size approx 6m x 3m. Should not exceed 20m square.